At a Glance:

- PTFE: Best for chemical resistance, low friction, and electrical insulation.

- PEEK: Superior strength, durability, and resistance to harsh environments.

- Cost Consideration: PTFE is more cost-effective, while PEEK offers premium performance for critical applications.

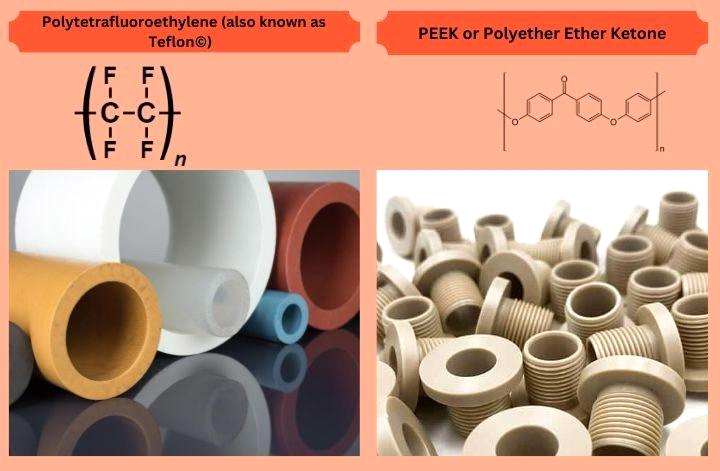

In Australia, two high-performance engineering plastics that stand out are PTFE (Polytetrafluoroethylene) and PEEK (Polyetheretherketone). Both materials are celebrated for their exceptional properties and versatility, yet they cater to different applications. This article aims to clarify the differences between PTFE and PEEK, helping you make informed decisions for your specific needs.

Understanding PTFE

PTFE, a well-known material also called Teflon©, is famous for its exceptional qualities, including strong resistance to chemicals and extreme temperatures, minimal friction, and excellent electrical insulation. PTFE plastic is very resistant and can be used in places with strong acids and bases.

PTFE is a thermoplastic, but its high viscosity means it cannot be processed using conventional polymer techniques. Instead, it undergoes cold shaping followed by sintering to form solid mouldings. This process allows PTFE sheets and other products to maintain their exceptional properties.

PEEK: The Premium Polymer

PEEK is a strong and durable thermoplastic that can resist chemicals and high temperatures. Unlike PTFE, PEEK can be processed using conventional methods such as injection moulding, extrusion, and compression moulding.

PEEK excels in environments where strength and durability are paramount. Due to its robust nature and long-term durability, it is used extensively in aerospace, automotive, and other demanding industries. However, because PEEK is more expensive than PTFE, it’s only used when its exceptional properties are essential.

Comparing Key Properties

Both PTFE and PEEK have distinct advantages and disadvantages, making them suitable for different applications. Here’s a detailed comparison to highlight their unique characteristics:

- Tensile Strength and Elongation

- PTFE: Tensile strength of 25-35 MPA and elongation of 350-400%.

- PEEK: Superior tensile strength of 90-100 MPA and elongation of 30%-40%.

- Preferred Material: PEEK for strength, PTFE for flexibility.

- Chemical and Temperature Resistance

- PTFE: Virtually inert, has excellent chemical resistance, and can withstand temperatures up to 250 °C.

- PEEK: Highly resistant but can be attacked by strong acids at high temperatures; also resists temperatures up to 250 °C.

- Preferred Material: PTFE for chemical resistance, both for temperature stability.

- Coefficient of Friction

- PTFE: Exceptionally low, between 0.03-0.05.

- PEEK: Higher, ranging from 0.35-0.45.

- Preferred Material: PTFE for applications requiring low friction.

- Electrical Properties

- PTFE: Excellent dielectric strength of 50-150 KV/mm.

- PEEK: Good dielectric strength at 50 KV/mm.

- Preferred Material: PTFE for electrical insulation.

- Cost

- PTFE: Moderately expensive but cost-effective for many applications.

- PEEK: Very expensive, reserved for critical applications where its properties justify the cost.

- Preferred Material: PTFE for cost-sensitive applications, PEEK for high-performance requirements.

Applications and Usability

PTFE and PEEK serve different niches within various industries. PTFE is perfect for seals, gaskets, and non-stick coatings in the food processing and pharmaceutical industries due to its low friction and chemical resistance. PEEK is commonly used in aerospace, automotive, and oil & gas industries for components such as bearings, valve parts, and insulators, thanks to its strong mechanical properties and thermal stability.

Choosing the Right Material

The choice between PTFE and PEEK hinges on your application’s specific requirements. If you need a material that offers unparalleled chemical resistance, low friction, and excellent insulation, PTFE plastic is your go-to. If your application requires a strong and durable material at a higher cost, PEEK is the best choice.

Understanding the differences between PTFE and PEEK is crucial for making informed decisions about selecting engineering plastics in Australia. Each material brings its unique set of properties to the table, making it indispensable in its respective domains. Epol, a leading PTFE supplier, offers a range of PTFE sheets and products tailored to your needs. Visit our website to explore our offerings and find the perfect material for your next project.