In industrial operations where precision, consistency, and efficiency are paramount, industrial gear pumps play a crucial role in fluid transfer systems. They are widely used in applications that require the movement of viscous fluids under controlled pressure. Understanding how these pumps work, their internal mechanisms, and their engineering advantages is essential for designing reliable and high-performance systems. This guide offers engineers a detailed look into how these pumps function, their types, applications, and key performance considerations.

Understanding the Basics of Industrial Gear Pumps

Industrial gear pumps are positive-displacement pumps designed to move fluids by using gears that mesh together. These gears trap the fluid between their teeth and the pump casing, pushing it from the inlet side to the outlet side. Because they deliver a consistent volume of fluid with each rotation, they are ideal for applications that demand precise and steady flow rates.

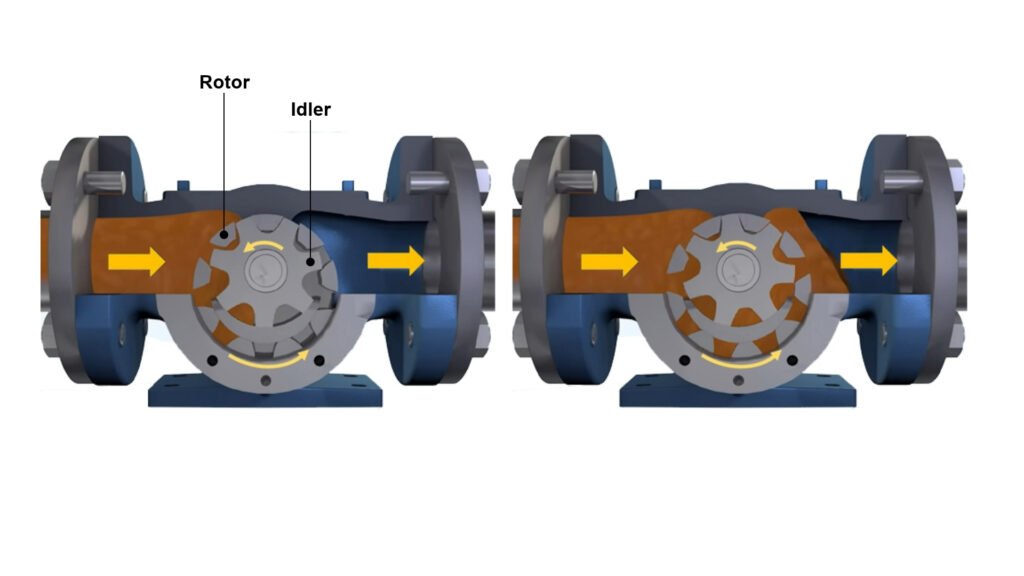

There are two main categories of gear pumps: external gear pumps and internal gear pumps. Both types operate on similar principles but differ in their construction and suitability for specific applications.

- External gear pumps use two identical intermeshing gears that rotate in opposite directions. They are known for their ability to handle high pressures and provide consistent flow, making them suitable for lubricating systems, chemical transfer, and hydraulic applications.

- Internal gear pumps feature a smaller gear (the rotor) inside a larger gear (the idler). This configuration allows them to handle higher viscosity fluids and provide smooth, low-pulsation flow. They are commonly used in industries where fluid shear must be minimized.

How Industrial Gear Pumps Work

At the heart of every gear pump lies the concept of displacement. When the gears rotate, the spaces between the gear teeth and the pump housing create small cavities. These cavities draw fluid in through the inlet as the gears unmesh. The trapped fluid is then carried around the outer sides of the gears and forced out through the outlet as the gears re-engage.

Here’s a step-by-step breakdown of the operation:

- Fluid Entry: As the gears start to rotate, the unmeshing of the teeth at the inlet side creates a low-pressure zone that draws fluid into the pump cavity.

- Fluid Trapping: The fluid becomes trapped between the gear teeth and the casing. This sealed space prevents backflow, ensuring accurate fluid displacement.

- Fluid Transfer: The trapped fluid travels along the housing from the inlet to the outlet side. During this motion, there is minimal leakage or slippage, contributing to the pump’s high volumetric efficiency.

- Fluid Discharge: As the gears mesh again at the outlet, the trapped fluid is squeezed out, producing a steady and controlled discharge pressure.

Because the fluid is moved by mechanical displacement rather than centrifugal force, gear pumps are capable of generating high pressure and maintaining consistent output, even with viscous or non-lubricating fluids.

The Role of High-Pressure Gear Pumps in Industry

High-pressure gear pumps are a specialized subset of industrial gear pumps engineered to handle challenging operating conditions. These pumps can generate substantial pressure levels, often exceeding several hundred bar, making them ideal for demanding tasks such as hydraulic power systems, lubrication circuits, and fuel transfer in heavy machinery.

Their rugged construction allows them to work efficiently in environments where reliability and performance are critical. In hydraulic applications, for example, they provide the power needed to operate cylinders, motors, and other mechanical components with precision. In chemical processing plants, high-pressure gear pumps are used to handle viscous or corrosive materials, ensuring consistent delivery without pulsation or cavitation.

Another advantage of these pumps is their ability to handle high-viscosity fluids, such as oils, resins, and polymers, which would challenge other types of pumps. Their positive displacement mechanism ensures that flow remains steady even as viscosity or system pressure changes.

Key Components and Materials

The performance of industrial gear pumps depends on their design and materials. Typical components include the gears, housing, shafts, bearings, and seals. These elements must be precisely engineered and manufactured to minimize wear and leakage while maintaining efficiency.

- Gears: Usually made from hardened steel, cast iron, or specialized alloys to withstand high pressures and frictional loads.

- Housing: Constructed from durable metals that resist corrosion, pressure, and temperature variations.

- Bearings and Seals: Designed to reduce friction and prevent fluid leakage, ensuring long operational life.

- Shafts: Support gear rotation and transmit torque from the drive motor or engine.

In certain applications, advanced materials such as stainless steel or composite coatings are used to improve corrosion resistance or handle aggressive chemicals.

Advantages of Using Industrial Gear Pumps

Industrial gear pumps offer several benefits that make them indispensable in engineering and manufacturing systems:

- Consistent Flow: Because they deliver a fixed displacement per revolution, they ensure accurate flow rates regardless of pressure changes.

- High Efficiency: They achieve excellent volumetric efficiency, especially in systems requiring constant output.

- Compact Design: Their simple construction makes them space-efficient and easy to install.

- High-Pressure Capability: Particularly with high-pressure gear pumps, they can handle demanding hydraulic and industrial applications.

- Versatility: Suitable for handling a wide range of fluids, including oils, fuels, and viscous liquids.

- Durability: Minimal moving parts lead to lower maintenance requirements and longer service life.

Applications Across Industries

Industrial gear pumps are used across various sectors, including manufacturing, chemical processing, automotive, and energy. They play vital roles in:

- Hydraulic systems for heavy machinery and construction equipment.

- Lubrication systems where continuous oil flow is essential for machine protection.

- Fuel transfer systems in engines and power generators.

- Chemical dosing and blending, where accurate metering is required.

- Paint, polymer, and adhesive production, due to their ability to handle viscous materials.

Their adaptability and precise control make them ideal for both low- and high-pressure operations.

Maintenance and Troubleshooting Tips

Although industrial gear pumps are robust, regular maintenance is essential for reliable operation. Engineers should routinely check for wear on gears, bearings, and seals. Any unusual noise, vibration, or drop in pressure could indicate internal wear or cavitation. Proper lubrication, alignment, and timely seal replacement are critical for preventing premature failure.

Regular fluid analysis also helps ensure that contaminants or debris do not damage the pump’s internal components. Choosing the right pump size, speed, and material based on the operating fluid and temperature can further enhance performance and longevity.

Industrial gear pumps are the backbone of numerous fluid handling systems in modern industry. Their simple yet effective design enables them to deliver accurate, steady, and high-pressure flow in a wide range of applications. For engineers, understanding how these pumps operate, how to select the right configuration, and how to maintain them effectively is key to achieving optimal system performance.

From powering hydraulic systems to transferring viscous industrial fluids, both standard and high-pressure gear pumps continue to demonstrate unmatched reliability and precision in industrial environments. As engineering technology advances, these pumps will remain a cornerstone of fluid transfer solutions, driving efficiency and innovation across countless industries.