Factory floors across America tell a familiar story. Monday’s success is Tuesday’s failure. A late supplier delays the week’s plans. New competitors pop up selling similar goods at lower prices. The days of making one widget the same way for decades? Gone. Winners today bend without breaking. They shift production runs midstream. They handle custom orders alongside standard batches. They fix problems before customers see them. This is the result of businesses prioritizing agility.

Building Blocks of a Flexible Factory

If you don’t see it, you can’t fix it. Therefore, visibility is key. Managers staring at week-old reports might as well be driving while looking in the rearview mirror. Fresh information changes everything. A conveyor belt slowing down triggers immediate investigation. Quality measurements drifting off target get corrected before scrap bins overflow.

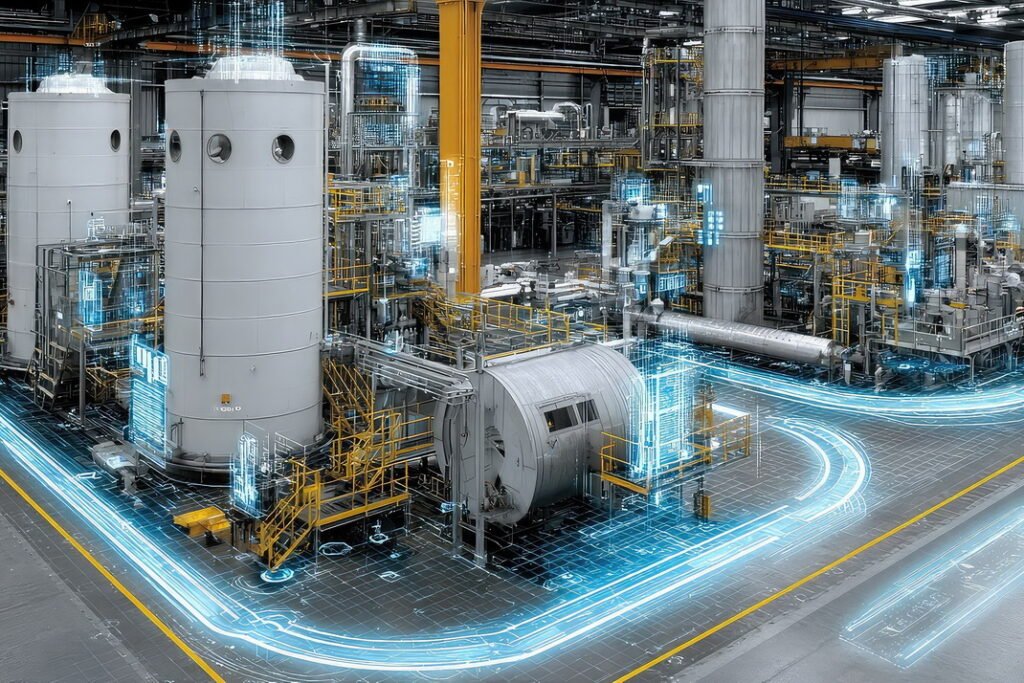

How do factories achieve this X-ray vision? Sensors. Lots of them. Tiny digital observers watching temperatures climb, pressures fluctuate, and motors strain. These electronic scouts feed streams of numbers into networks that turn chaos into clarity. One dashboard shows maintenance crews which bearings run hot. Another helps schedulers see bottlenecks forming three stations ahead.

But here’s where it gets interesting. When different systems share notes, magic happens. The warehouse management system tells production what’s running low. Production alerts purchasing about upcoming material needs. Quality control data flows back to adjust machine settings. Everything clicks together, humming along even when surprises pop up.

Technology That Actually Works

Plenty of factories have closets full of abandoned gadgets. Expensive scanners gathering dust. Software licenses nobody renewed. The problem? Buying tech for tech’s sake instead of solving specific headaches. Industrial IoT solutions have come a long way from their clunky beginnings. Blues IoT stands out among providers making these connections both practical and budget-friendly for manufacturers big and small. These platforms revitalize older machines. That stamping press from 2005? Now it texts maintenance when it needs oil. The packaging line installed during the Bush administration? It tracks output rates and flags slowdowns instantly.

Cloud services add rocket fuel to these capabilities. Forget about server rooms and IT headaches. Today’s analytics run through web browsers, accessible from anywhere. Updates occur without interruption. Storage adjusts to usage. You pay only for what you use.

People Power the Change

Gadgets are useless if workers won’t use them. Flexibility lives in human adaptability. The operator who knows three different machines becomes invaluable when orders shift. Teams comfortable swapping roles keep production moving when someone calls in sick.

Smart companies teach constantly. Not boring PowerPoints in stuffy rooms, but hands-on learning that sticks. Virtual reality goggles let newbies practice dangerous procedures safely. Lunch-and-learn sessions spread tricks from old-timers to rookies. Online modules fill downtime productively. Every brain that gains knowledge makes the entire operation stronger.

Making It Happen

There’s no quick fix for agility. Slow progress is better than none. Identify your biggest problem. Maybe it’s that one machine that always breaks unexpectedly. Connect it. Monitor it. Repair it before it breaks. People will ask for more after seeing the change. Pushback happens. Some folks worked the same way for 20 years, so why change now? Others fear robots stealing jobs. Listen to these worries. Address them honestly. Show how better tools make work less frustrating, not less human. Share victories loudly. Let skeptics become believers through results, not arguments.

Conclusion

Standing still means falling behind. That’s the brutal truth of modern manufacturing. Watch everything closely. Connect the dots between different systems. Trust people with information and authority. Move fast when conditions change. If you do these things often, even old factories will be like startups. Don’t delay. The cost of waiting is greater than the cost of acting.